By Bill Bregar

SENIOR STAFF REPORTER

Published: September 26, 2014 12:30 pm ET

Updated: September 26, 2014 1:02 pm ET

SCHAUMBURG, ILL. — Heavy-duty equipment used to arrange and re-set bowling pins netted three awards for Associated Thermoforming Inc. in the parts competition at the Society of Plastics Engineers Thermoforming Conference.

ATI, which is based in Berthoud, Colo., also won in the pressure formed category, for a cover for a medical smoke removal system.

Stephen Zamprelli, parts competition chairman, said 25 parts were entered, even one from India. “We had some great products out there,” said Zamprelli, vice president of product development for Formed Plastics Inc. in Carle Place, N.Y.

Judges were Roger Kipp of Roger C. Kipp Sr. & Associates, and Ian Strachan of ToolVu.

ATI molds the thermoformed bowling pin resetter parts for QubicaAMF, the bowling products supplier — to replace metal with plastic. According to A.J. Stoneburner, estimator and sales engineer at Associated Thermoforming, ATI and the customer worked together for seven years to develop the pin elevator, which collects pins and orients them before depositing them on the other thermoformed part with cavities to hold the pins — called the Durabin.

Image By: QubicaAMF

The complete pinsetter package.

Development of the Durabin took one year, he said. Each one of the 10 cavities for the pins has a different wall thickness in unique areas, since the pin-setting device deposits each pin into place at a different angle and specific impact zone.

ATI used computer-aided design, with detailed information from the customer, to design the part and individual plug assists.

By using a PVC track for the chain drive that moves the pins up through the elevator apparatus, QubicaAMF has improved the working lifetime of the chain, said Paul Gleason, PTI process engineer.

Stoneburner said the new mechanism also enabled a better-looking, space-saving design in plastic. “The big thing by moving to that chain drive: They were able to make an oblong shape instead of a circle,” he said.

The bowling pin equipment won the heavy-gauge vacuum forming award, the twin-sheet award, and the People’s Choice Award, voted on by conference attendees.

Award winners were honored at a dinner on Sept. 16 at the conference in Schaumburg. For the second year, the SPE Thermoforming Division held a student awards competition. First prize, and a $1,000 award, went to Jerrold Ancheta of San Jose State University for a vacuum formed trans-radial prosthesis. Madeline Freding of the University of Wisconsin Stout picked up the $500 second place price for her product, called Re-Form.

Here is a recap of the 2014 winners:

Image By: SPE Thermoforming Division

Lindar Corp.'s tamper-obvious cake package.

Roll-fed, food grade

Lindar Corp. of Baxter, Minn., won for its two-piece cake package with a tamper-obvious closure. The package has two performance innovations to allow the vendor to thaw and sell frozen treats: A perimeter ventilation to allow the package to breath. A slightly domed top area disperses condensation to the perimeter area of the dome. Each package is designed to allow retailers to stack them.

The cake package is formed from recycled-content PET on a six-cavity aluminum tool. According to Lindar, it was a challenge to do proper trim registration and consistent perforations.

Roll-fed industrial, gold

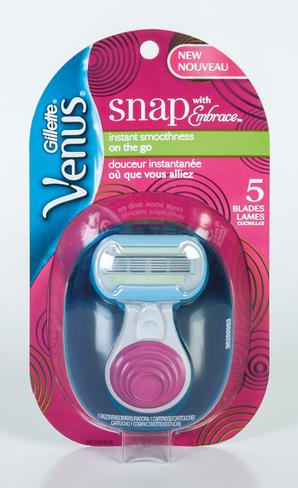

Think4D Inc. of Altona, Manitoba, won the gold award for the roll-fed industrial category, for a blister package for the Gillette Venus Snap Razor. The pre-printed PET dome is formed in precise registration with the razor, enticing customers to pick up and feel the package, according to Think4D.

The package uses 73 percent less plastic that previous Venus packaging, and is 27 percent lighter. A smaller package, with a 53 percent reduction in packaging materials, means the product can be packed more densely for distribution. Making the package smaller, the razor was placed in a reusable travel pod.

Think4D pressure formed the package on aluminum tooling with six cavities per index, from roll-fed sheet.

Roll-fed industrial, silver

The silver award went to Innovative Plastech Inc. of Batavia, Ill., for a set of interlocking trays to hold and display products in retail refrigerators. Plastech thermoforms the three trays from black recycled PRET. The black color helps to draw more attention to the product, not the tray.

The modular trays are snapped together, using a single rail snap for easier closure, instead of competing trays that use several smaller snaps. The positive portion of the snap is machined in pieces so it can’t be confused with the negative snap. Also, to drain off water in a wet-spray refrigerator, Plastech designed an extended S-curved shape, for stability, instead of the standard straight drainage channels or holes punched all over the tray.

Pressure-formed, gold

ATI officials stayed on the podium to grab the pressure-formed gold with a housing used in a smoke evacuator in medical elecro-surgical procedures. The part demands a very severe draw ratio to get the plastic all way down to the bottom. ATI does that in a negative mold with many undercuts, especially a very deep one in the rear of the part. The key is automated lifter core pulls around the perimeter. Also, the back section of the mold has a core-pull. ATI also uses a pneumatically articulated plug assist to get the needed uniform wall thickness into the rear section.

The sheet is fire-retardant Kydex-T.

Image By: SPE Thermoforming Division

Think4D Inc. won for the blister package of the Gilette Venus Snap Razor.

Pressure-formed, silver

Silver in the pressure-formed category went to Saint-Gobain PPL in Puyallup, Wash., for a nine-part package that create an enclosure for a robot being developed by Adept Technology in California for laboratories and SC wafer fabrication, in clean rooms.

The parts must fit with very tight and even parting lines, according to Saint-Gobain. That required all but two of the parts having deep draws and undercuts. Tooling is CNC-machined from an aluminum billet that is gun drilled with water cooling lines. One part has a silk screened Adept logo.

Twin-sheet, silver

Profile Plastics Inc. of Lake Bluff, Ill., won the silver award for a twin-sheet, pressure formed spine board used to transport victims for medical treatment. Molded from ABS sheet, the board has molded-in straps.

Profile uses two textured, machined aluminum, water-cooled pressure form tools to create a single hollow shape with 22 pinch regions.

It has a slip-resistant surface.

Combined category:

roll-fed or heavy-gauge

The award went to Universal Protective Packaging Inc. of Mechanicsburg, Pa., for a patented Geospring thermoformed recycled HDPE end-cap packaging for the hard disk drive industry.

Universal forms the parts on a Sencorp 2500 thermoforming machine using roll-fed black sheet.

Because of the size of the mold, maintaining optimal mold temperature and ensuring adequate material distribution over the mold presented challenges. The mold’s temperature was controlled by using bubbler baffles, and material distribution was overcome by using a plug assist.

The end cap gives maximum protection during transportation with its spring system, which uses harmonic bellows that form a flexible ridge for shock and vibration absorption. When dropped from a height, the rapid deceleration caused by the impact engages the spring system and efficiently dissipates the shock and vibration. Also, the end caps are compact, lightweight and nestable, reducing box size and warehouse space requirements.

Combined category:

innovative part

Philadelphia-based CW Thomas LLC won for an airline seat pocket assembly using three thermoformed components and value-added fabrication. Two of the parts are pressure formed and one is vacuum formed. All three molds are single cavity tools, CNC machined aluminum. There is an aluminum brace in this unit also.

CW Thomas forms the parts using custom-colored, aircraft-grade acrylic-PVC.

All parts are trimmed, and the hole positions for assembly are routed.

CW Thomas officials said the plastic seat pocket saves weight, and reduces costs, from the traditional metal assemblies.

Combined category:

value-added and assembly

Specialty Manufacturing Inc. of San Diego won for an assembly for a large medical device, made from pressure-forming, including some twin-sheet parts.

The material is custom-colored acrylic/PVC, made on textured tools, machined from block aluminum.

Specialty Manufacturing assembles the glass to the upper housing, to reduce assembly time for the customer.

|